A holistic approach to Asset Management and cost efficient operation.

We can support you in optimizing the life cycle of your plant, risk reduction, cost optimization, and streamline operation and maintenance by usage of the industry´s leading methods and tools.

Our effective and proven methodology can help you to achieve next step in your journey towards excellence.

ICONconsultancy

Your next step towards operational excellence!

We can support you in optimizing the life cycle of your plant, risk reduction, cost optimization, and streamline operation and maintenance by usage of the industry´s leading methods and tools.

Our effective and proven methodology can help you to achieve next step in your journey towards excellence.

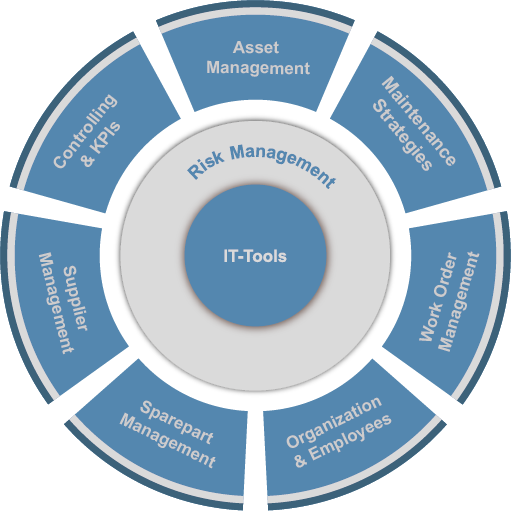

Our Methodology

Optimization potentials:

Optimization potentials:

- Establishment of an Asset Management System:

- Definition of objectives, vision, missions for Asset Management and development of Strategic Asset Management Plans (SAMP)

- Ingetration of life cycle management principles

- Development of Asset Management Plans (AMP)

- Decision making and planning

- Implementation of Maintenance Policies (e.g.. TPM, Lean, Autonomous, etc.)

- Configuration Management

- Improvement of HSE Management in technical areas

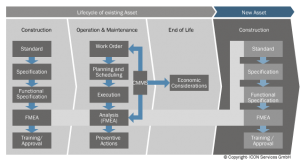

Principles of life cycle oriented Asset Management:

Your benefits:

- Aligned and coordinated policy, strategies and activities within the Asset Management

- Organizational optimization of trans-sectorial life cycle management (silo-effect)

- Optimized leadership decision making

- Implemented project- and configuration management

- Motivation of workforce through objectives and aligned approaches in the organization

- Evaluation of entire performance and effectiveness

- Safety first!

- Cost efficiency throughout every life-cycle phase

Optimization potential:

- Definition of operational maintenance strategies of assets and technical components:

- Inspection, scheduled maintenance, repair, improvement (DIN31051)

- Preventive Maintenance (PM) & Predictive Maintenance (PdM)

- Reliability Centered Maintenance (RCM), Condition Monitoring (CM), etc….

- Development and Optimization of individual –aligned with maintenance strategies – maintenance plans

- Development of maintenance plans for Autonomous Maintenance

Principle overview of the approach for definition operational maintenance strategies:

Your benefits:

- Increased availability and effectiveness (OEE) of plant assets

- Discover non conformities trough preventive maintenance and decrease the firefighting mode

- Usage of potential of condition-based maintenance

- Usage of maintenance intensity which it´s necessary because of criticality

- Usage of necessary maintenance measurements and methodologies to prevent downtime

- Optimized resource capacity through optimized planning

- Increased planning ratio within your organization

Optimization potential:

- Development of individual work order management and processes

- Implementation of the continuous improvement principles in the processes

- Implementation of operational planning functions in the organization

- Establishment of a planning and scheduling culture for efficient job control

- Establishment of a continuous improvement culture for elimination of losses

- Definition of auxiliary processes

Principle of optimized maintenance process:

Your benefits:

- Definied and optimized processes accordingly quality management requirement within your asset and maintenance management departments

- Increased productivity through work order control and planning process

- Maintenance = planning! Not even firefighting!

- Efficient usage of resources (personnel, contractors, material)

- Identification of the cost drivers – integrated into daily planning process and continuous improvement

- Usage of given information, data, experiences

Optimization potential:

- Definition and implementation of proactive-oriented organizational structure

- Improvement of personnel productivity

- Alignment and optimization of wages structure

- Leadership & workforce development

- Transparency of knowledge (competences and qualifications)

- Communication and information plans

- Documented information management according quality management

Principle of a optimized organizational structure for Asset Management:

Your benefits:

- Optimized organizational structure with meet requirements of asset management

- Best practice in personnel productivity

- Defined requirement and leadership culture

- Performance-linked wages based on and optimized maintenance functions

- Long-term personnel development programs

- Aligned job descriptions (rolls, competences, responsibilities, awareness)

- Attractive functions and career models with the Asset Management and Maintenance organization

- Defined communication and information management

- Optimized documented information management

Optimization potential:

- Definition of Spare part strategies

- Material management optimization methodologies (like ABC analysis)

- Gap alignement (target – current situation)

- Optimization of warehouse management

- Optimization of inventory level

- Optimization of purchasing management for spare parts

- Spare Part logistics and processes

- Alternatives like consignation, ecommerce, kanban, etc.

Principle of the Pareto rule, which shows that only 10-15% of spares are really critical:

Your benefits:

- Cost savings in material costs

- Increased cash flow trough savings in capital costs

- Efficiency in spare part strategies

- Balanced inventory stock between risk and stock optimization

- Economical stock control

- Defined processes in warehouse and purchasing

Optimization potential:

- CAPEX/OPEX planning

- Definition and development of an individual reporting system

- Definition of useful KPI´s

- Definition of performance evaluation and object targeting

- Definition of costs and activity accounting

Your benefits:

- Usage of an individual and appropriate cost and performance reporting system

- Target-oriented control and decision making in the field of asset and maintenance management

- Given performance evaluation and monitoring processes

- Responsibility of objectives, their performance and counter measures

- Definition and rules for CAPEX and OPEX planning

- Long-term and short-term planning

- Transparency in the organization

Optimization potential:

- Definition and implementation of a risk management system

- Development of a risk management tool

- Definition of responsibilities and authorities

- Development of Risk management process:

- Risk identification

- Risk analysis

- Risk evaluation

- Risk treatment

Your benefits:

- Planning and minimization of organizational risk within the area of Asset Management and Maintenance

- Risk classification of the assets

- Increased probability of targeting objectives

- Increased bargaining power for assurance negotiations

- Increased confidence of customers

- Erhöhung der Wahrscheinlichkeit zur Zielerreichung

- Compliance accordingly „Cooperate Sector Supervision and Transparency Act“ in technical organizations

Optimization potential:

- Definition of criteria for selection of a new system

- Support for tendering process

- Evaluation and comparison of different systems (by more than 200 criteria)

- Support for Implementation of CMMS

- Development and optimization of master data collection

- Optimization in effectiveness of current exiting systems

Your benefits:

- Optimized utilization of a CMMS

- Acceptance of the system by workforce

- Implemented tool to ensure compliance to work

- Commons system for work order management, planning, scheduling, reporting, resource planning and further more!

- Adaption belong to individual objectives and strategies

- Continuous Improvements trough optimized CMMS!

We adhere to the latest international standards for the related fields.

- ISO 9001 Quality Management

- DIN 31051 Maintenance

- ISO 55001 Asset Management

- DIN EN 31000 Risk Management

- DIN 69901 Project Management